Manufacturing, Planning & Scheduling

MetricsERP provides a powerful and intuitive Manufacturing, Planning & Scheduling for the Small and Medium Businesses

Manufacturing module in the MetricsERP application suite facilitates and manages various aspects of the manufacturing process. It is designed to streamline operations, increase efficiency, and provide real-time visibility into the production cycle.

MetricsERP manufacturing module includes functionalities such as:

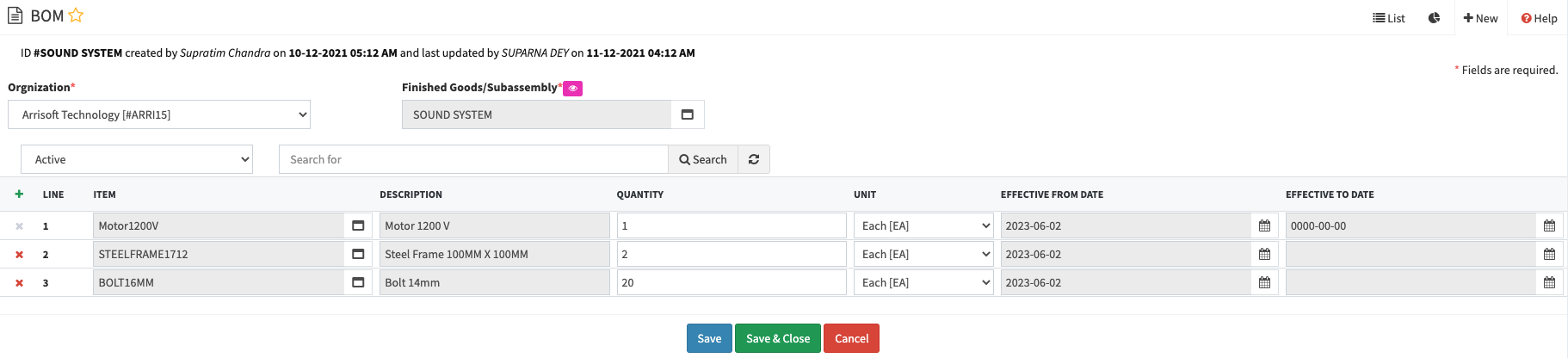

Bill of Materials (BOM) Management:

BOM management allows the creation and maintenance of detailed lists of components and materials required to produce a finished product. It includes information about quantities, specifications, and relationships between different components.

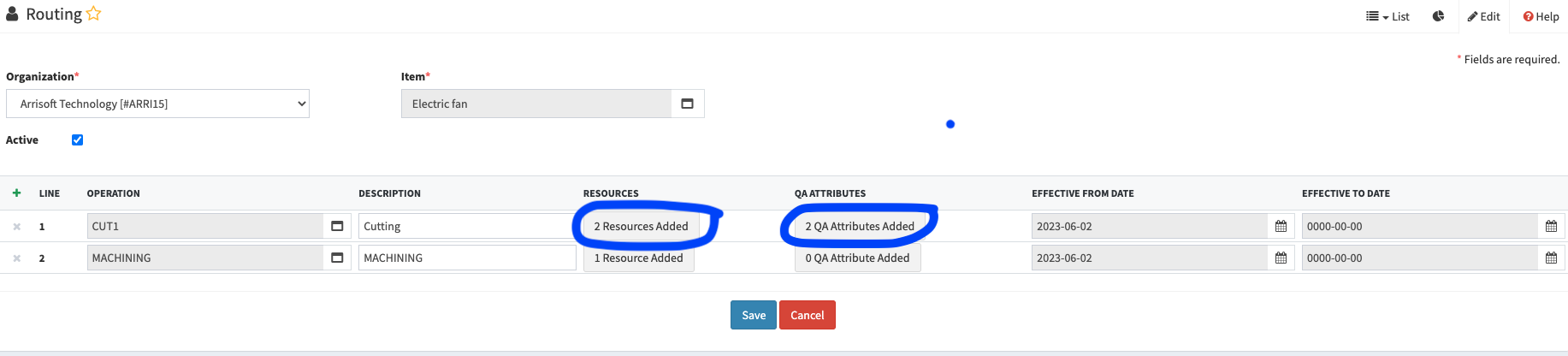

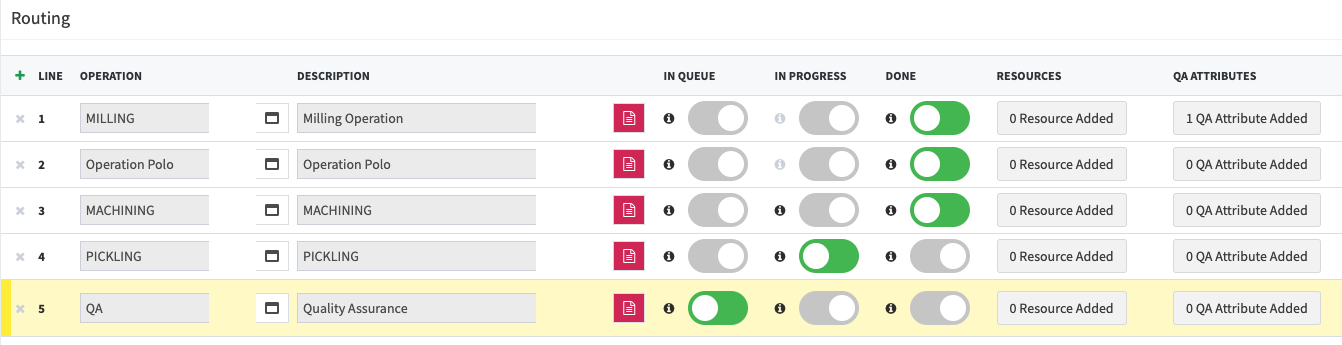

Routing Management:

Routing management allows the creation and maintenance of detailed lists of manufacturing operations and related manufacturing resources to be involved to produce a finished product. Routing also allows defining all the quality management parameters along with their expected values and tolerances.

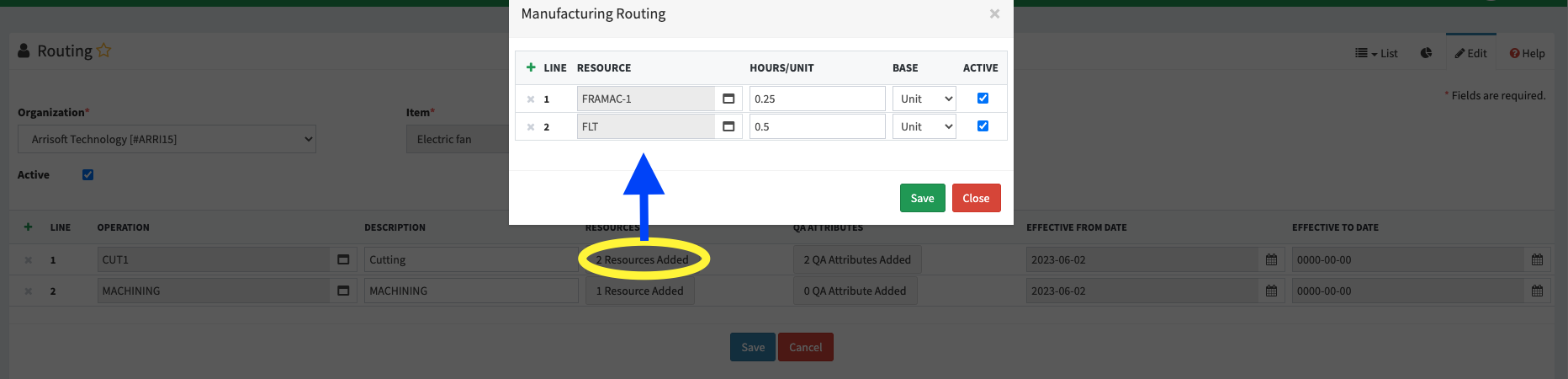

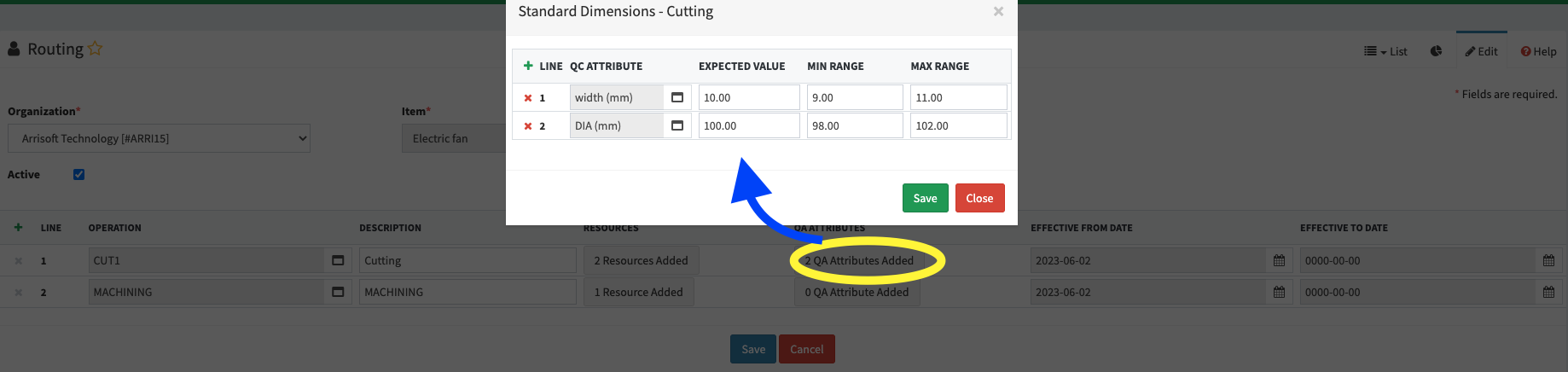

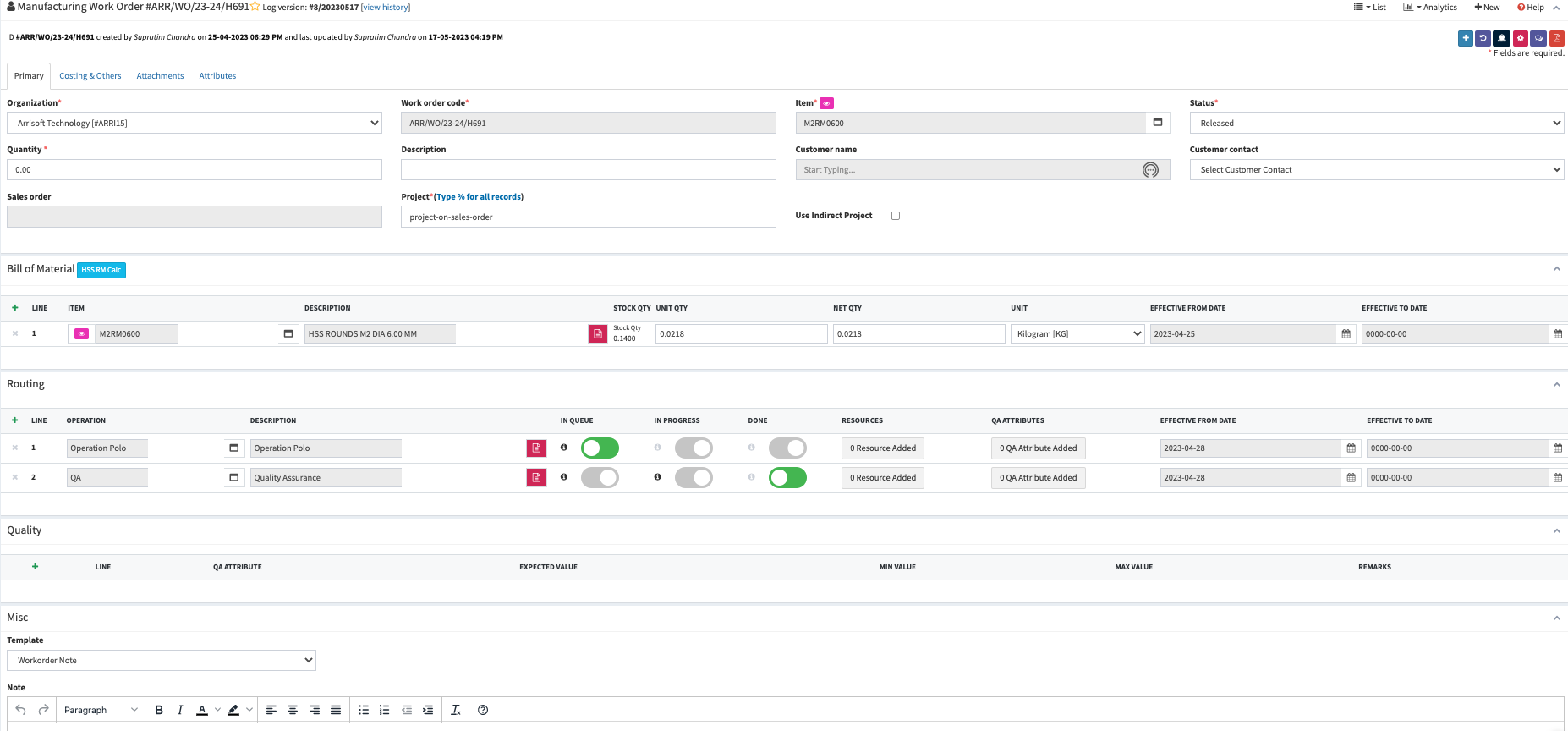

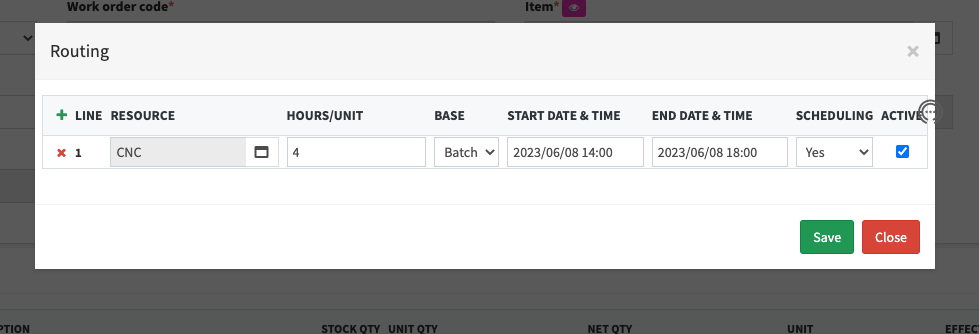

Above screen shot shows the Routing definition page in the MetricsERP application. Please note the “Resources” and “QA Attributes” button, as the “Resources” button allows defining all the resources required to complete the operation specified and the “Quality” button allows defining all the quality measures to be achieved for the specific operation. Following screenshots depict the “Resources” and “Quality” definition sections. These pop-ups will be opened once clicks on the “Resources” and “Quality” buttons respectively.

We can specify multiple resources against an operation. The page also allows specifying the time required for each unit/batch. Please note – MetricsERP allows defining 3 types of resources in the Resource Master (i.e. People, Machine, Vendor).

Above screen shows the quality attributes definition pop-up related to the Routing definition page in the MetricsERP application. As shown above, the system allows defining multiple quality attributes for an operation as well as specifying the expected value and tolerances.

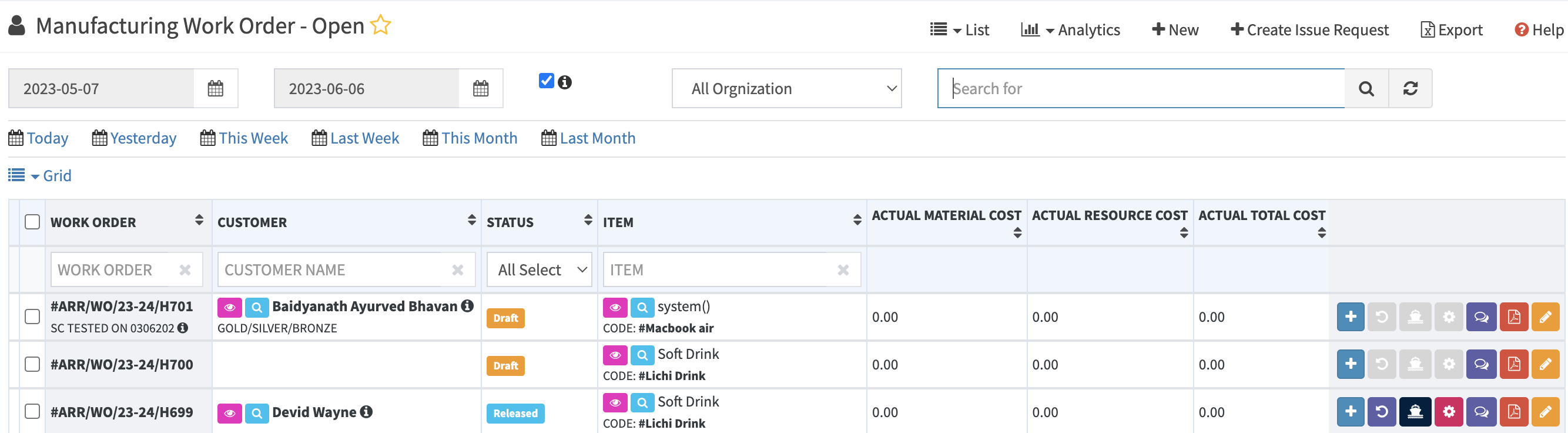

Work Order Management:

MetricsERP Manufacturing module includes a comprehensive Work order management capability that enables the creation, tracking, and scheduling of production orders. It includes assigning resources, allocating materials, and monitoring the progress of work orders through various stages of production. Following screenshot shows the Work Order Page that contains multiple sub-sections related to BOM components, routing steps, quality management, cost tracking etc.

MetricsERP Work Orders can be created from multiple sources, such as – just by clicking a button on the sales order, or from the material planning workbenches, i.e. Min/Max planning, Reorder Planning or MRP (Material Requirements Planning).

Each Production order can be mapped/pegged directly to a sales order to track the specific demand being fulfilled by the work order. In addition – project based organizations can map a project directly to a MetricsERP work order.

Production Planning and Scheduling:

This functionality helps in creating production plans and schedules based on factors like resource availability, capacity, and demand. It allows users to optimize production timelines, manage dependencies, and avoid bottlenecks. MetricsERP Work Order derives the required operation and related resources and quality attributes directly from the routing master of the respective Finished Goods. The same can be manually added or edited directly into the Work Order as well. Following screenshot will show each operation resource is flagged with a planned start and finish date for the production scheduling purposes.

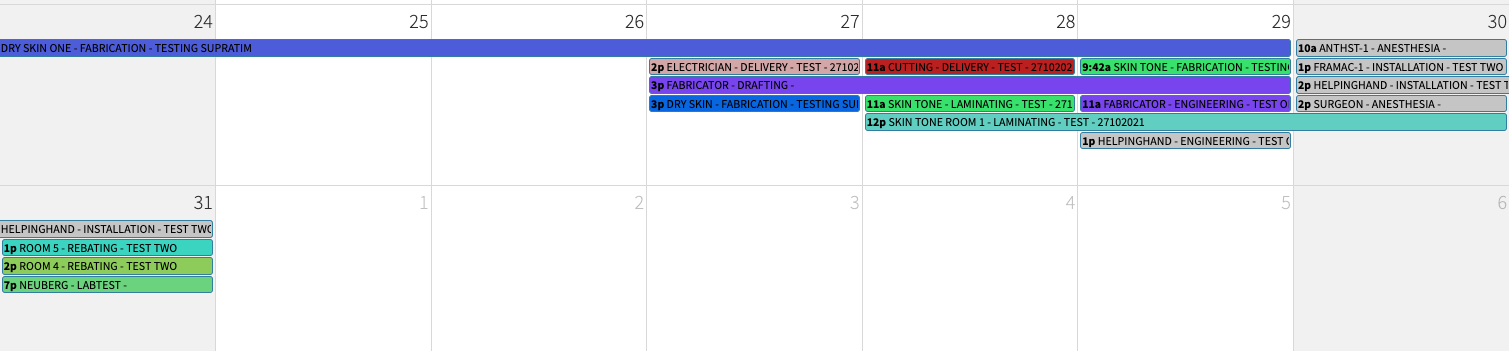

All scheduled resources appear in a graphical resource workbench (screenshot below) for the user to analyze the upcoming production plan, resource workload and potential bottlenecks. The workbench provides the ability to analyze data based on specific, work order, resources etc.

Inventory Management:

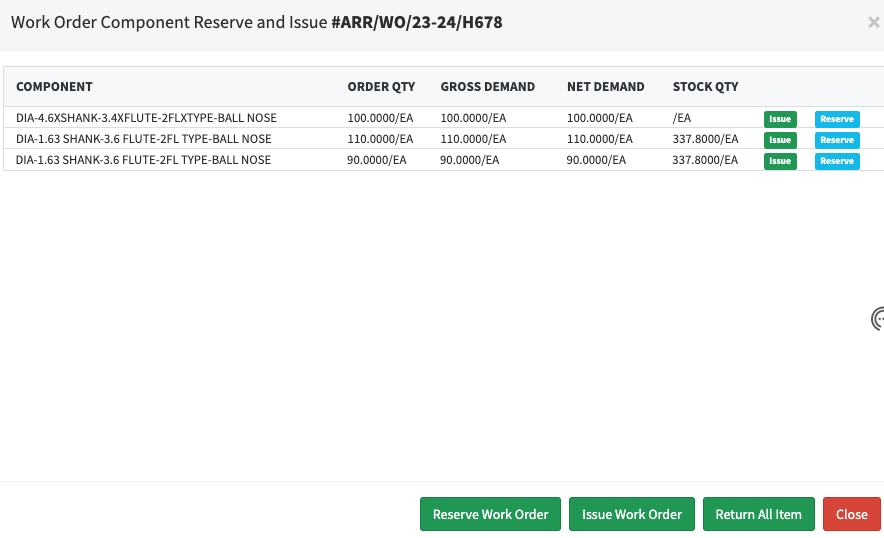

The manufacturing module integrates with inventory management to track and manage raw materials, work-in-progress (WIP), and finished goods. It helps in maintaining optimal inventory levels, reducing stockouts, and managing stock movements across the production cycle. MetricsERP work order allows one button click material reservation and issue process as per the Bill of Materials (BOM) specified in the work order. It also allows transferring stock from one store to another in order to stage all materials required for multiple work orders by clicking a button. The work order listing page shows real time material reserved and issue percentages for the users to track the material status against the work order BOM.

We can reserve/issue BOM components fully or partially. The above window also allows one button click return for all work order BOM components as well.

Shop Floor Control:

Shop floor control capabilities enable real-time monitoring and control of manufacturing operations. It includes features like data capture, production tracking, and quality control to ensure that the manufacturing process is running smoothly and efficiently. MetricsERP Work Order module contains a very intuitive shop floor control mechanism that allows flagging the queue/in progress/done stage of each manufacturing operation just by clicking a button. System also allows one-click operation to send finished products from the quality department to rework.

The Shop Floor control capability is not limited to tracking progress of the internal shop floor operations only, as it also tracks outside processing operations by creating purchase orders directly from the work order for the operations involving subcontractors.

Above image shows the Shop Floor control mechanism for a particular work order. A “Rework” button will automatically appear as soon as the Finished Products come to the QA Department.

Quality Management:

Quality management functionalities within the manufacturing module help in defining quality standards, conducting inspections, and managing non-conformances. It ensures adherence to quality control processes and enables continuous improvement initiatives. MetricsERP Work Order will automatically fetch the quality attributes and expected values and tolerances directly from the Routing data. The same can be added and edited into the work order itself. Following screenshot shows the quality management section of the MetricsERP Work Order.

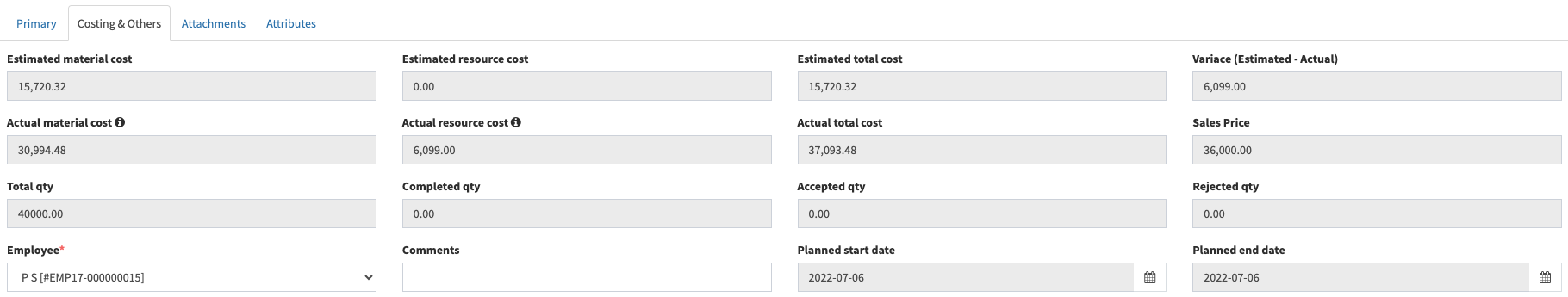

Costing and Financial Management: The manufacturing module integrates with financial management to track costs associated with production. It helps in calculating the cost of goods manufactured, analyzing production expenses, and providing insights into profitability. MetricsERP Work Order tracks estimated, actual and variance (estimated – actual) cost for both material and resources. Resource cost includes costing related to all kind of resources (i.e. Machine, People, Subcontractors etc.). Intuitive user interface allows cost analysis by drilling down into each cost factor effectively.

Reporting and Analytics: The module often includes reporting and analytics capabilities that provide real-time insights into production performance, resource utilization, inventory levels, and other key metrics. It helps in making data-driven decisions and identifying areas for improvement.

The built in data drilldown, advanced search, export and emailing capability helps users extract, analyze and share the business critical data with their peers and management in order to facilitate appropriate decision making.